Label application method is a key factor in determining long term benefits of the production line. Speed and accuracy plays an important role in the entire process, without which things can get cluttered and expensive. There are different ways in which labels can be applied onto your desired surfaces, and enlisted below are some of them:

Hand Labeling

Certainly the most conventional method of label application, hand labeling technique has been in the picture even before the invention of custom printed labels or printers. It requires cautious placement of the label on the product, with perfect alignment. This kind of appliance requires manual skills, rather than equipped machineries. Just make sure you are not getting any paper cuts!

Hand-Held Applicator

Hand-held applicators are a convenient and fast way to manually apply pressure sensitive labels to your products. Available in a variety of sizes, these applicators are perfect for applying labels to small batches of cartons and products. Not only does it help speed up the accuracy of production, but also reduce any chances of misalignment.

Single Automatic Applicator

It’s a little tricky to label round containers such as jam, craft beer or wine bottles. Single Automatic Applicators reduce labor costs and offer easy entry into automation for low-volume packaging operations of round beverage bottles. You can do both front and back labeling with the labels going on straight. The automatic system integrates easily on different packaging lines for operational flexibility.

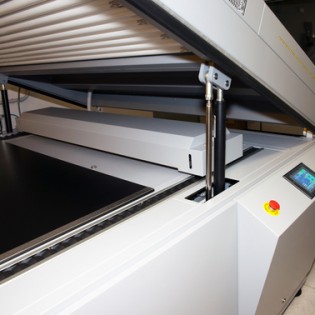

Fully Automatic Applicator

Fully automatic applicators are designed for higher speed production lines with high-volume packaging operations. It can lay down labels up to 4.7” wide and 11” long, labeling up to 164 feet per minute. These smooth functioning applicators are low maintenance, with sturdy metallic built.

Label Printer Applicator

This 2-in-1 applicator saves both your time and money on printing custom labels and affixing them on the product. Combining the high density label printer with an automatic applicator, simultaneously print and apply labels to the sides, tops or bottoms of products along the conveyor line. This instrument can fit the requirement of any industry, as you completely eliminate the expense of pre-printed labels.

High Speed Print Apply System

High Speed Print Apply System is extremely beneficial for shipping and distribution processes. A typical system includes print/apply machine, conveyor for labeling, inducting and discharge and a scanner to read the printed label. With a capacity to print and apply over 40 labels in a minute, it’s both a time and cost-efficient method.

As evident from above, there are different ways to suit different requirements. Hand labeling is the simplest one, but requires more labor and time. On the other hand, round bottle labelsfind their refuge in automatic applicators for perfect application on the product. If you are high on demand, requiring faster production lines, print/apply system is all you need to match the supply requirements. Label printer applicators are more complex systems, which can be accessed from different locations and be customized for a wide variety of applications.