Not all cosmetic labels apply the same rules when it comes to design. There is a variety of cosmetic products for different applications and use. There are those that need to be used in humid conditions while some in dry places. Others may contain medicinal values while some don’t. This means that a company has to design custom cosmetic labels depending on the shape and size of the container, product content and conditions under which the products will need to be stored.

However, there are basic procedures that every cosmetic company needs to follow to ensure successful cosmetic label printing. These include:

Choose Right Materials For Containers

Are your containers plastic or glass, squeezable tubes or rigid, opaque or clear? You cannot use just any label material on any container. To achieve a great look, you need to find a material that will be practical depending on the type of container you use. For example, if a container is clear, you need to use clear liners to allow consumers to see the contents. If your container is squeezable, the material you choose needs to be strong enough to withstand abrasion.

Laminate For Protection

Most cosmetic products are handled frequently and they are usually applied after people get from the shower. This means that a product has to withstand abrasion frequently and may sometimes be exposed to wet conditions. Durability of your cosmetic labels is of much importance. You need to laminate your labels to protect them from daily handling, heat, moisture and scratches. Laminating labels also prevent the ink from running or fading with time.

List Ingredients

No matter what design you choose for your cosmetic labels, you must allocate space where you will list ingredients. According to the FDA regulations, all cosmetic labels should list manufacturer information, Allergan statements and ingredients in an easy to read font. This information needs to be displayed either on the back label if a container has the front and back labels, or the side panel of the container.

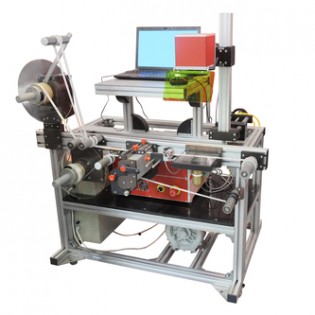

Choose A Printing Process

Do you want your labels to be printed in color? How many labels will you need to print? Answering these two questions will help you determine whether you need to work with a label printing company or take care of label printing in-house. If you require huge label orders at a time, it would be advisable to have a printing company take care of your label needs to save on costs. If you are a small company that does not require large quantities of labels, it is best to invest in a compact digital label printer. Over time, digital printing has dominated over traditional methods of label printing because it is fast and affordable.

Prepare Labels For Marketing

Labels are not just meant to provide information to the consumers. They have multiple functions from inventory control to price tagging and marketing. Take advantage of these other uses. Design a label that can function as a marketing tool as well. How? By incorporating barcodes and QR codes. These codes can be scanned by consumers to direct them to a landing page that will provide more information about the product that could not be displayed on the product labels.