Label liners are often overlooked but they usually play a very crucial role in creating successful food labels. What is a liner? Liners are basically a film or paper backing which helps to protect the adhesive on a label before final application. While choosing which label material to use for their food labels, most producers will overlook on which liners to use and this can often lead to losses.

If you end up using the wrong liner on your food labels, it can lead to wasting label material, production delays or even failure of adhesion leading to lost time and money. So how do you pick the right liners for your food labels?

How To Pick Liners

Before picking the right liners for your food labels, you need to ask yourself how you intend to apply the labels. There are two main methods used when applying labels and they include by hand or machine.

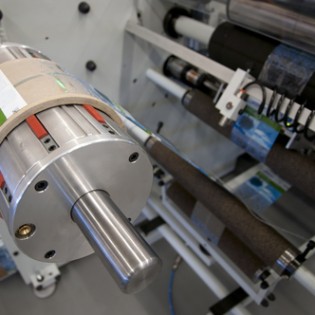

These two methods require different liners. Hand applied labels need manual release so that means that liners need to be flat and may need a slit back if the sheet label is large in size. On the other hand, machine dispensed labels can use two types of liners namely fan-fold or roll.

These liners are dimensionally stable and strong so that they can easily be dispensed through the machines without tears or jams. You need to ensure that the liners you choose release easily otherwise the labels will not be properly applied. If the liner is too loose then they increase the chance of contamination from external particles leading to adhesion failure.

Types Of Liners

Basically, there are two types of liners namely: paper and film.

Paper liners: Paper liners are widely used on food labels the main reason being they are cheaper compared to film liners. Paper liners have to go through a smoothening process and then they are coated with silicon to keep them from sticking on adhesives. They are available in a variety of colors, calipers and weights.

Film liners: Unlike paper liners, film liners are more resistant to tear and they have a consistency in thickness which makes them a better choice for die cuts. They cost more than paper liners but they are very durable and they do not react when exposed in high humid environments. When paper liners are exposed to high humidity, they tend to curl up which affects the adhesion. Liners are available in clear or opaque and also available in different calipers and weights.

Choosing which type of liner depends on a number of factors and some of these include: budget, label size, dispensing method, and type of adhesive to be used. If you are not sure which liners to use on your food labels, consult with your label printer to help you pick the right liner. The label printing company will know which liner to use since the type of printer they will use will also be a determining factor. Ensure that you work with a reputable label printing company to get quality food labels.